A 5-week investigation into the family of form and manufacturing processes through the lens of a chess set that is:

Cohesive

Comprised of both static and casted components

Out-of-the-box

This project pushed me to learn two intimidating manufacturing processes: resin casting and metal working with a lathe and mill.

Objective

Futurism is a 20th century Italian artistic movement that served to replace traditional artistic values with boldness and dynamism. It typically involves eye-catching colors like red and black and symbols of movement like cars and trains. I was drawn to the style because I found its ability to communicate energy with soft curves intriguing.

Research

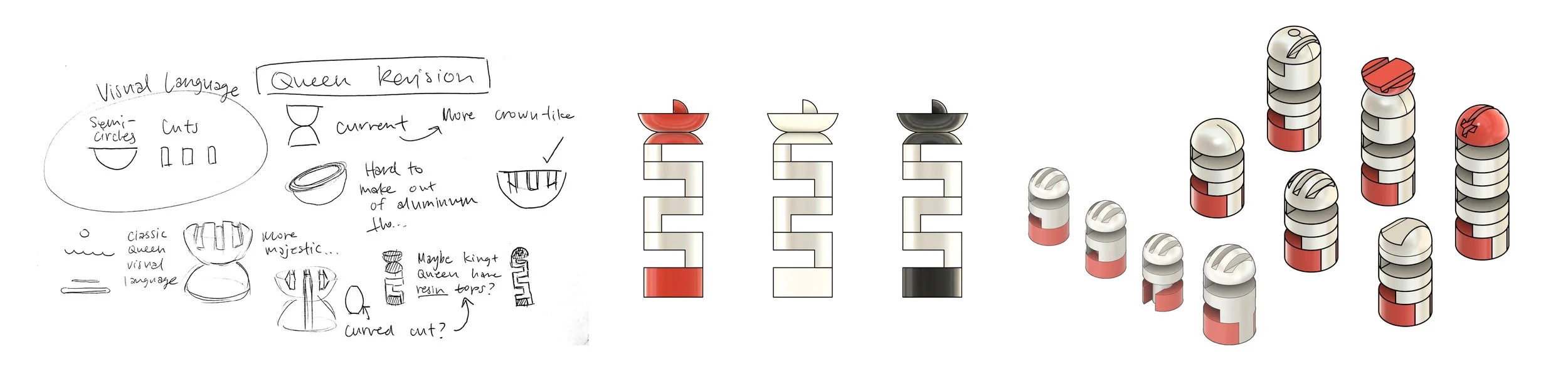

Though I took multiple approaches to creating families of form with distinct archetypes, I favored the aesthetic of simple, modular designs throughout the ideation phase. I was drawn to my gravity-defying cylindrical concept because their tiered appearance made it easy to adjust the heights of more powerful pieces, and their silhouettes were characteristic of Futurism.

Ideating

I moved forward with the less decorative direction, knowing I’d have to strengthen the visual hierarchy. I corrected issues with height (the bishop was originally taller than the queen), and wrestled with ways to make the royal pieces feel “grand” within the confines of my chosen streamlined aesthetic. In the end, I decided to give them an extra pop of color to set them apart from the group.

Refining

I decided to make my static components out of metal, because the material is historically representative of progress. This led to a big pivot, however, because I learned that the domes I had planned would be extremely difficult to execute with a lathe and mill, especially as a beginner. Though it was unplanned, I enjoyed the new angular look, because the pieces ended up resembling train whistles.

Metal

My grip test confirmed that my pieces fit on a standard chess board and were comfortable to hold, before I refined my cast pieces. The set was required to include common components that were 3D printed, molded, and cast in resin (I also opted to make crowns for the king and queen). This process involved a lot of trial and error. Even after producing a large quantity of casted bases and crowns, I had to sand and polish the most successful ones to arrive at my finished product.