Objective

A 5-week focus on user-centered design through the lens of chimney swift housing that is, to the primary and

secondary user:

Functional

Accessible

Attractive

This project required me to dive deep into the needs of an unconventional user and produce a large-scale wood product for the first time.

Research

The chimney swift population is declining. Due to deforestation, they rely completely on man-made structures. Their unique foot structure prevents them from perching normally, so they use glue-like saliva to stick their nests to vertical surfaces. Despite causing no damage, they are considered nuisances by homeowners whose chimneys and silos they nest in. Providing chimney-like structures for homeowners and institutions to invest in would keep the birds safe and residents unbothered.

Ideating

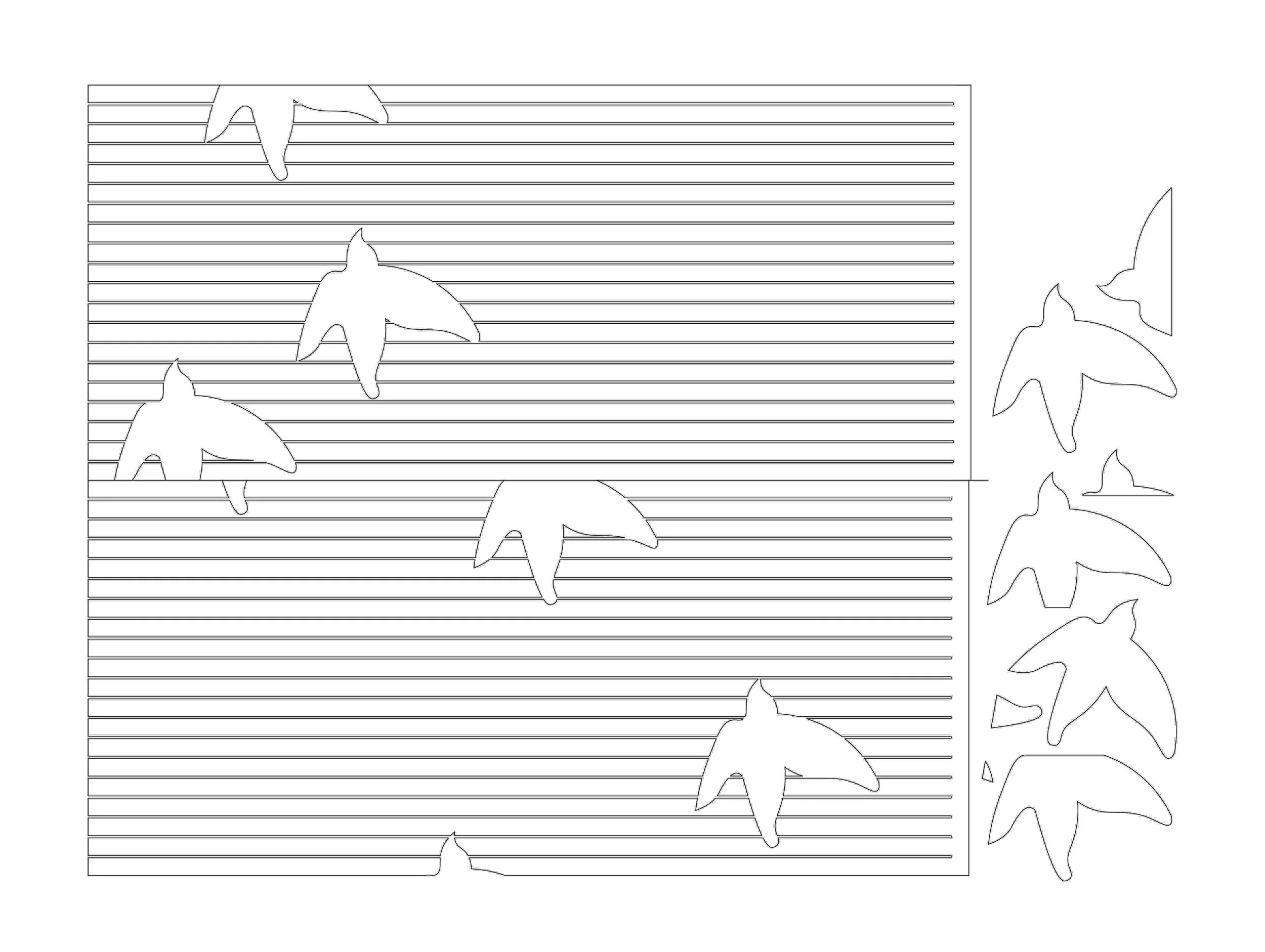

Existing solutions are about 15” squared and 4’-12’ tall in order to accommodate the thousands of birds that can nest together at a given time. I made mine as compact as possible at 4’ tall to make it approachable to the typical homeowner. My sketches were constrained to these proportions. I moved forward with concepts that mimicked aerial views and utilized dynamic swift silhouettes to add some energy to my plain form.

Refining

I crafted three low-fidelity models of potential directions, but was most drawn to the “inside/out” puzzle look of my third. It created elegant visual interest without adding much more dimension or weight to the already

hefty design.

Wood

Especially when painted white and paired with insulation, wood is the best material at maintaining safe bird house temperatures. A lot of tools I used for this project were new to me, such as the drill press and plunge saw, so I decided to make my avian sanctuary at half-scale. For the opening at the top, I leaned into the chimney aesthetic, with beveled edges, to make the structure more recognizable to the birds.

Finishing Up

I intended to laser cut the slats and silhouettes, but found that the process was expensive and lengthy. I revised my laser cutting file to include only cuts that would be difficult by hand, and completed the rest on a band saw. It’s recommended that swift towers are cleaned annually, so I laid out some strategies for lowering the box to the ground that would make the trap door at the bottom easily accessible without a ladder.